Work will be performed in Cincinnati, and is expected to be complete by July 11, 2032.

The contract came from the Air Force Life Cycle Management Center, based at Wright-Patterson Air Force Base.

The soon-to-be renamed GE Aerospace — also known as GE Aviation — is a big employer in Southwestern Ohio. Pre-pandemic, the company had about 1,500 employees working in four Dayton-area facilities, sites which saw a $1 billion total annual investment. About 9,000 Ohioans work for the company in total.

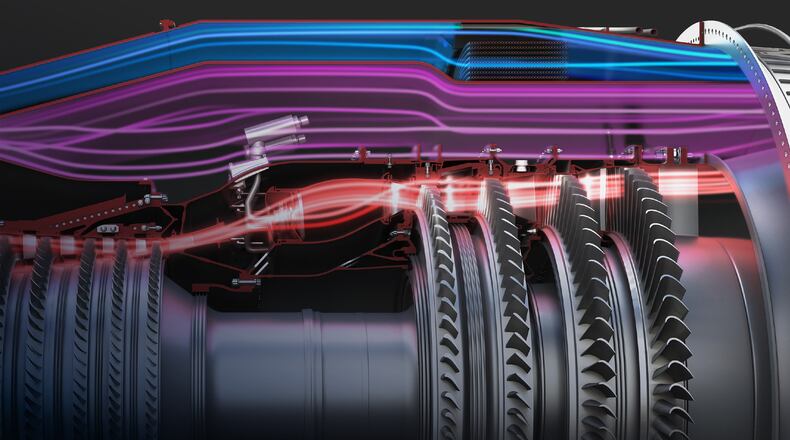

The company has pursued its XA100 Adaptive Cycle engine for some time, and concluded the first phase of testing on its second XA100 in Evendale late last year.

GE says the engine is designed to fit both the F-35A and F-35C without structural modifications to either airframe, enabling better range, acceleration and cooling to accommodate next-generation mission systems.

A GE spokesman for the XA100 program referred questions to the Air Force Life Cycle Management Center (AFLCMC).

But work on the engine itself is not new. Work by GE on the “adaptive” engines — a three-stream adaptive cycle engine with greater range and thrust — started more than a decade ago in Southwestern Ohio. Development of the XA100 has already supported jobs in the region and created new jobs.

There are only two adaptive engines in existence today — the GE XA100 and Pratt & Whitney’s XA101.

The Propulsion Directorate at the AFLCMC has more than 600 employees managing more than 22,000 engines on more than 30 different weapon systems, for the Air Force and 50 international partners. The directorate has a $3.4 billion portfolio.

Also chosen by the Department of Defense in the Next Generation Adaptive Propulsion program: Raytheon Technologies Corp. and Pratt & Whitney Engines, in East Hartford, Conn.; the Boeing Co., St. Louis, Mo.; and Lockheed Martin Corp., Lockheed Martin Aeronautics Co., of Palmdale, Calif.

Each contract has a value up to $975 million.

About the Author